Electrostatic Disinfecting Services

As a fellow local business, we know how important it is to ensure your employees and customers can safely and confidently enter your facility, especially during the reopening phases that will continue throughout the year. Our highly trained response teams partner with you to create a safer, cleaner environment for returning employees and customers. We provide varying levels of service for both Commercial and Residential facilities with tailored solutions to meet each client’s budget and virus-prevention needs.

EPA Approved Disinfectants

Newly Restored, in combination with Healthy Building Standards, and Electrostatic tools are providing state-of-the-art disinfecting services for commercial businesses in the South Central Pennsylvania area. We use EPA approved disinfectants (EPA Registration No. 87508-3) containing Chlorine Dioxide – Cl02 which has been used as a disinfectant for many years. We can follow that process up with application of an anti-microbial coating that adds an additional barrier against re-infection for up to 90 days!

Learn more about how electrostatic sanitizing works, the benefits of our products versus others being advertised, and the safety of our coatings and disinfectants.

Pricing

While it costs less than you think to disinfect a commercial facility, there are many variables involved when pricing out a building. Square footage, accessibility, furniture, walls, etc … all factor in, and make it difficult to provide a estimated price. However, we would be happy to come out and see the space and provide you with a FREE estimate. Contact us for a time when it is convenient to come out. By the way … we are currently running a promo for 10% off our disinfecting services!

Our Process

Step 1

Once the facility has been cleaned, we ensure that the surfaces being disinfected would be clear of papers, or other items.

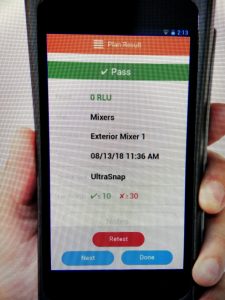

We would then take an initial reading of ATP (Adenosine triphosphate) levels in the room for a baseline reading. ATP is an organic compound found in all forms of life.

Step 2

Next we would apply a hospital grade disinfectant using an Eletrostatic Sprayer, or Ultra Low Volume fogger. This ensures complete coverage of product on all surfaces.

Next we would apply a hospital grade disinfectant using an Eletrostatic Sprayer, or Ultra Low Volume fogger. This ensures complete coverage of product on all surfaces.

Step 3

Next we allow the product to sit for at least 10 minutes. This ensures an effective kill rate.

Next we allow the product to sit for at least 10 minutes. This ensures an effective kill rate.

Step 4

Following the dwell time, we would wipe down all hi-touch surfaces with a microfiber towel to ensure complete removal of any and all pathogens. Each room would use their own towel to prevent cross-contamination.

Following the dwell time, we would wipe down all hi-touch surfaces with a microfiber towel to ensure complete removal of any and all pathogens. Each room would use their own towel to prevent cross-contamination.

Step 5

Once the room has been wiped down, a protective coating can be applied. This coating will provide an anti-microbial barrier against re-contamination for up to 90 days.

Once the room has been wiped down, a protective coating can be applied. This coating will provide an anti-microbial barrier against re-contamination for up to 90 days.

Step 6

A second reading is taken by the ATP meter to show levels in the room as a measure of outcome. The goal is reduction of ATP to acceptable levels as determined by the CDC. Acceptable ATP levels differ between public areas, food prep, and healthcare facilities.

A second reading is taken by the ATP meter to show levels in the room as a measure of outcome. The goal is reduction of ATP to acceptable levels as determined by the CDC. Acceptable ATP levels differ between public areas, food prep, and healthcare facilities.

Step 7

Once the coating has been allowed to dry on the surface, the room can be returned for occupancy. Standard housekeeping protocols can be implemented without risk of coating removal.

Once the coating has been allowed to dry on the surface, the room can be returned for occupancy. Standard housekeeping protocols can be implemented without risk of coating removal.

Frequently Asked Questions:

Do you use products that are EPA approved?

Yes. All of the products we use contain disinfectants that meet EPA’s criteria for use against SARS-CoV-2 – the novel corona-virus that causes the disease COVID-19.

Is it safe to use around my children or pets?

We have different solutions for different applications. When used where children or pets are concerned, we use solutions that are no more toxic as vinegar. We do, however, recommend removing children and pets from the areas where we are sanitizing.

Is it safe to use around electronic or electrical components?

Because the water droplets are so small (40 microns) one droplet from a conventional sprayer has the volume of over 1,000 droplets from an electrostatic sprayer. This eliminates the potential of water damage. Plus since no two droplets can occupy the same space on a surface, it eliminates possible over spraying or puddling from occurring. As a result, this form of sanitizing is perfect for cash registers, ipads, or other computer equipment.

Does the surface need to be cleaned before Disinfecting?

Yes. The surfaces should be pre-cleaned to remove any and all organic material from that surface. In fact, most chemical disinfectants can’t do their job when high levels or organic soil are in the way. Soil can absorb the active ingredient, provide more places for the germs to hide, and change the chemical nature of the disinfectant.

What is the difference between Sanitizing and Disinfecting?

Sanitizing is meant to reduce, not kill, the occurrence and growth of bacteria,

viruses and fungi.

Disinfecting a surface will “kill” the microscopic organisms as claimed on the

label of a particular product.

I hear terms like viruses, germs, and bacteria. Are they all the same thing?

Not exactly. First off bacteria are minute life forms which can cause infections in humans. They have the ability to adapt quickly to their surroundings. Their goal is to survive and multiply. They can be good for you (think yogurt, probiotics, etc …), or bad for you. Bacteria, unlike viruses, can stay on a surface for days, months, even years if there is enough soil to sustain it.

Viruses are smaller than bacteria. Picture a virus the size of a marble. A bacteria could be the size of a human by comparison. They require the cells of a living organism to grow and reproduce. They need a human host to survive, but can survive for a limited time outside the host. Viruses can die quicker than bacteria. Anti-biotics have no effect on viruses, but can kill bacteria which have not developed a resistance to them.

Germs is not a scientific term. Germs is a broad term to include bacteria, viruses, or fungi and can infect humans and animals. A better term would be pathogenic organisms or pathogens.

I use a chemical disinfectant with a trigger sprayer. Is that sufficient for me to disinfect my facility?

It depends. When it comes to disinfecting fomites (objects or substances – other than food – which harbors or carries infectious organisms), it is important to read the label completely, and then ABIDE by the label. It is not a guideline. To be effective at killing pathogens, a product sprayed onto the surface must remain for at least 10 minutes. Unfortunately, many people spray and then wipe the surface almost immediately. This had done nothing more than moving microbes around. Additionally, when you use that cloth on another surface, you have now cross contaminated that new surface with the microbes from the first. ALWAYS allow for dwell time and use a new cloth for each surface or room.

Is there a way to protect the surfaces against recontamination after the area has been disinfected?

Up until a few years ago, the answer would have been no. You would have been required to have the professional come back either daily, bi-weekly, or weekly to reapply the disinfectant to the space. This could get costly and rendered no protection between re-applications.

However, technology has triumphed again. There are silane based protectants that coat a surface using a molecule with 2 parts. These two parts have been spliced together to produce a patented technology. The base of this molecule forms a tenacious bond (covalent) to the treated surface (porous or non-porous). The second layer sets up a cross-linking chain forming a microscopic bed of carbon spikes that puncture the cell walls of microbes as they come to rest on a treated surface. These columns of positively charged carbon atoms pierce microbes and electrostatically shock

Newly Restored has these coatings available for application.